(1) Working principle

Electrostatic sorter is a method which uses the difference of the electrical properties of each component in the solid material in the high voltage electric field to realize the separation. The material in electrostatic sorter is charged by direct conduction. When the material directly contacts with the conductive electrode, the material with good conductive performance will get the charge with the same polarity as the electrode and be repelled. When the material or non-conductor with poor conductive performance contacts with the charged drum, it will be polarized, and the opposite bound charge will be generated at the end near the drum and attracted by the drum, so as to realize the separation of different electrical materials.

(2) Scope of application

It is suitable for the separation of materials with different conductive properties of each component, such as the separation of some metal ore, the separation and recovery of steel scrap, etc. In the electronic waste recycling processing line is mainly used to separate the mixed materials into semiconductor, plastic, non-ferrous metal three parts.

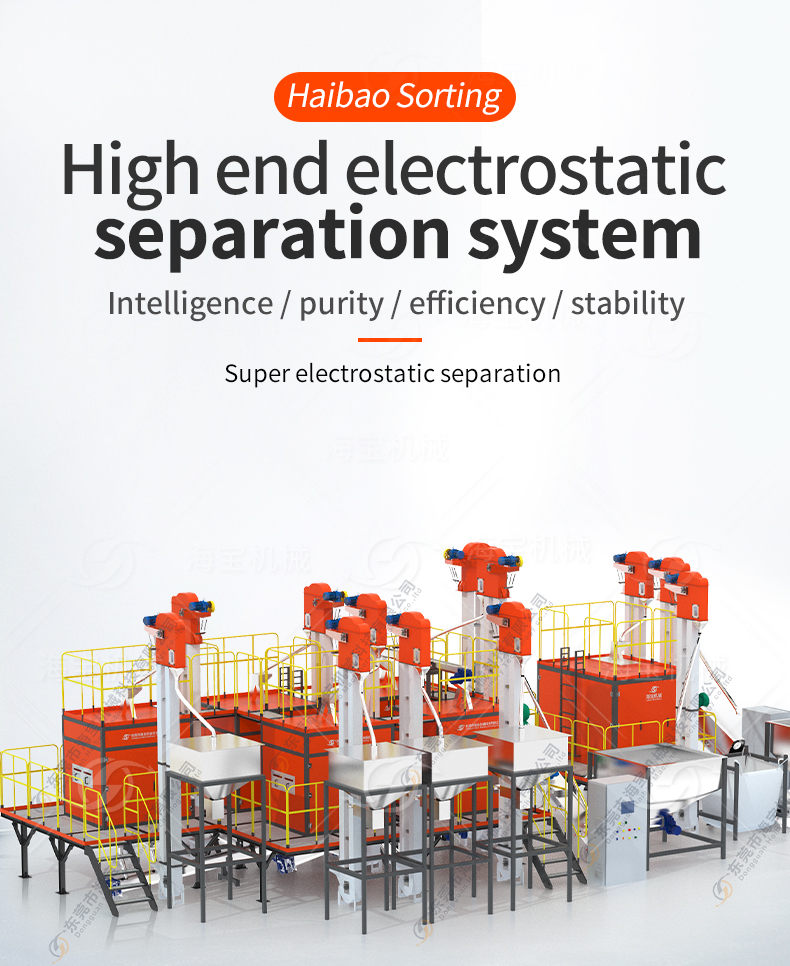

(3) Structural characteristics

The main components of electrostatic sorting equipment are a negatively charged insulating drum and a set of positive electrodes close to the drum and the feeder. When the material is close to the surface of the drum, due to the induction of the high-voltage electric field, the surface of conductor particles will be polarized and positively charged, which is attracted by the polymeric electric field of the drum. After contact, it will be negatively charged due to conduction, repulsed by the roller under the action of Coulomb force, and fall out of the roller. Insulator does not produce the above effect, is quickly dropped by the roller, to achieve the separation of conductor and insulator.

Electrostatic separator features:

* The use of multiple corona electrostatic composite arc structure electrode, the use of long hole flow vibration feeder and suitable for fine powder mechanical dredging type feeder;

* With wide corona field area, special blanking device, anti ash leakage measures;

* High electric field strength, stable mechanical and electrical performance, high sorting efficiency, low energy consumption;

* The machine has good sealing performance; Reasonable structure, compact, large processing capacity;

* Heating device is arranged in the sorting cylinder;

* Electrical control adopts PLC control programmable controller and frequency conversion governor, with safety protection, emergency stop and other facilities, to ensure the sorting quality and mechanical and electrical performance stability.

Send your message to us:

Post time: Nov-01-2022